About MTWB Bearings | Hong Kong Precision Bearing Manufacturer

Mighty Way Industrial Limited (MTWB) is a Hong Kong–based bearing supplier specializing in precision miniature ball bearings, deep groove ball bearings, and custom OEM bearing solutions.

⚙️ High-Precision Bearings Built to International Standards

MTWB partners with five leading factories in mainland China, each equipped with advanced production lines, automatic inspection systems, and full testing equipment.

All bearings are manufactured to ISO 9001 / ABEC / P6 or higher precision grades — ensuring stable performance, low noise, and long service life comparable to major global brands.

✅ Precision class P6 or higher

✅ Noise level Z1,Z2,Z3 optional

✅ ID range from 0.6mm to 380 mm

🔧 Customized Bearing Solutions (OEM / ODM)

We provide custom-made bearings to meet unique customer requirements, including:

• Non-standard dimensions

• Special materials or seals

• Small-batch prototype orders

Our experienced engineers and sourcing team offer complete technical support — from sample design to mass production — making MTWB an ideal OEM bearing partner for international brands.

💰 Competitive Pricing with Assured Quality

As a Hong Kong-registered company with a China manufacturing base, MTWB combines international trading standards with local production efficiency.

This unique structure allows us to provide premium-grade bearings at highly competitive prices, delivering “International Quality — China Cost.”

Industries

- ✓ Aviation Instrument

- ✓ Medical Instrument

- ✓ Encoder / Decoder

- ✓ Home Electricals

- ✓ Office Equipment

- ✓ Macro/DC/AC Motor

- ✓ Fitness Equipment

- ✓ Industrial Robot

- ✓ Power Hand-tools

- ✓ CNC Machine

- ✓ Agri. Machinery

- ✓ Forklift, Elevator

- ✓ Oil Pump

- ✓ Two Wheeler

- ✓ Power Transmission

- ✓ Glass & Ceramic Tile Manufacturing

- ✓ Fluid Machinery

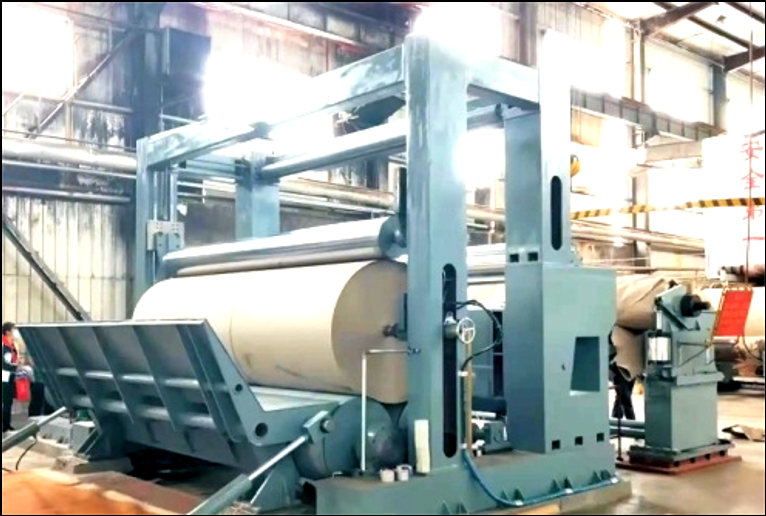

- ✓ Metals Industry

- ✓ F&B Packaging

- ✓ Food Processing

- ✓ Construction Machinery

Automotive

- ✓ Power System

- ✓ Steering System

- ✓ Transmission System

- ✓ Chassis System

- ✓ Auxiliary System

- ✓ Electric Vehicle

Each application benefits from our bearings’ smooth rotation, minimal friction, and consistent reliability.

🌍 Global Reach and Service

From our Hong Kong headquarters, we serve customers across Europe, North America, and Asia.

We focus on professional communication, fast response, and reliable export logistics — helping our clients achieve long-term success in global markets.

💡 Our Mission

To deliver high-precision, cost-efficient, and customized bearing solutions for global OEMs and distributors — combining Hong Kong reliability with China’s manufacturing strength.

Over the last 30 years, our factories have accumulated vast bearing and application experiences in:

History

30+ Years

Annual Production Capacity

30 Million Sets

Product

1,665 Variants

Employees

212+ Persons

History

60+ Years

Annual Production Capacity

2 Million Sets

Product Types

150 Variants

Employees

60+ Persons

Manufacturing Excellence

MTWB bearing is produced by either manual or fully automatic lines to the standard of

leading international OEM. Product reliability is ensured by advanced production equipment, complete range

of testing instrument and a strong technical team.

Bearing Life

Larger sized bearings have a finite life under use and will eventually fail to perform

satisfactorily due to an increase in noise and vibration, loss of running accuracy, deterioration of

lubricant, or fatigue flaking of the rolling surfaces. Such failure modes are considered "normal" and can be

predicted using standardized techniques. In addition to normal deterioration, bearings may fail due to heat

seizure, fracture, scoring of the rings and other conditions caused by improper use, selection or

maintenance of the bearing. Such failures are not normal and can only be avoided by careful handling and

correct operation of the bearing in a given application. Never the less, under ideal working conditions, the

so-called infinite bearing life is possible!

Torque

Small diameter ( < 20 mm OD) deep groove ball bearings have extremely low and uniform

torque characteristics. Even when preloaded as part of an assembly, average torque levels of less than

0.5 gm-cm (0.007 oz-in) are common. Typically, torque is dependent on many factors, including ball size,

number of balls, retainer type and looseness, radial play, lubricant type and fill percentage, and

applied load.

Super Precision Miniature Bearings

MTWB continuously seeks for technical improvement and up till now can provide you with a full range

of miniature bearings from 0.6-30mm ID (Designation: 68/0.6~6806 or RO~R10). Yes, as small as 0.6mm

ID, up to ABEC-7 precision class! It is by far the smallest miniature bearing that you can find on

earth.

Our success for making this world’s smallest miniature bearing is originally driven by medical

application, yet we believe this technology can also be extended to other industrial application.

All our miniature bearings are made from international graded bearing steel to ensure their

excellent loading and service life performance.

Our miniature bearings are found everywhere for examples in micro motors, medical and aviation

devices, instruments, meters, electronic devices, disc-driver, computerized sewing machines, robotic

arm, drones, household appliances, office equipment and high-altitude weather monitoring devices.

Extra Low-Noise Small DGBB

MTWB deeply understands that different applications or industries have the same stringent

requirement for bearing noise, such as electric motor, household equipment, automobiles, aviation

and so on. Materials matter! That's why we choose only the finest bearing material, like G95Cr18, or

GCr15 bearing steel or corrosion-resistant 300-series stainless steel. These top-graded materials

ensure MTWB bearings are strong, durable, and whisper-quiet to perform flawlessly for long haul.

One key factor to make a low-noise bearing lies in reducing vibration that relies much on our

top-notch technicians to refine every possible way to grind the inner ring raceway of our low-noise

bearings with minimal vibration – in fact, even to ensure they always exceed the industry standards

by 2-3 dB!

MTWB doesn't just say our bearings are quiet, we guarantee it. Firstly, we prevent dust and debris

entering the interior of the bearing before sealing or shielding the bearing. Secondly, we use only

good quality balls and grease that is another major factor influencing bearing noise. MTWB bearings

are lubed with lithium-based grease for closed bearing. Special grease can be selected according to

OE customer’s requirement. Finally, 100% inspection is conducted on the sealing effect of every

bearing before it leaves the factory.

In order to accurately grade the noise level of bearings, we strictly follow the testing

specifications and make full use of noise testers and vibration testers for inspection. The noise

detection of bearings is divided into Z1-Z4 levels, while the vibration detection levels are

classified as V1-V4. OE customers usually have stricter requirement for bearing noise, yet they can

select their acceptable noise level hence yielding the best cost advantage.

Special Dimension Bearings or Precision Components

Usually special dimension bearings or precision components are designed by OE customer for

functionality or cost-saving reasons or both. MTWB can made-to-order according to customer’s print,

or real sample provided. Your inquiry for this service is most welcome!

Mounting and Fitting

Many small bearing performance problems are caused by a lack of understanding of the effects of

tight tolerances combined with the reduction in bearing radial play caused by interference with

mating parts. Miniature bearings can have very thin inner and outer ring cross-sections (< .008" in

some cases). When such a bearing is pressed onto a shaft or into a housing, depending on the

material, up to 80% of the interference fit translates into loss of radial play in the bearing.

For a bearing that has (say) .0002" to .0004" radial play in the first place, normal tolerance

stack-ups can cause immediate bearing failure.

Packing

Industrial packing is applicable by default, special requirement should be mentioned when

ordering. MTWB miniature bearings are usually put into plastic tubes or polythene bags and

then packed in boxes or cartons.

中文(简体)

中文(简体)

中文(繁體)

中文(繁體)

日本語

日本語

한국어

한국어

ไทย

ไทย

Español

Español

Deutsch

Deutsch

Italiano

Italiano

Français

Français

English

English